Physicochemical properties of enamel glazes

The physicochemical properties of enamel glaze are usually divided into the following categories:

I. Mechanical properties

Second, thermal properties

Three, optical properties

Four, chemical stability

Five, enamel other properties

Mechanical properties are subdivided into:

(A) tensile strength

(B) compressive strength

(C) flexural strength

(D) elasticity

(E) hardness

(F) density

(G) impact strength

(H) Adhesion strength

Last issue, we introduced the mechanical properties of tensile strength and compressive strength, this issue, we will introduce the bending strength and elasticity.

(iii) Bending strength

The bending strength of porcelain enamel refers to the ability of porcelain enamel to resist bending under the action of external force, and the test method is to place the pivot points of both ends of the specimen on the test frame, and add pressure in the center until the specimen is fractured, and the pressure value at this time indicates the bending strength of the porcelain enamel, and the unit is Pa.

The bending strength of porcelain enamel and its chemical composition, Na2O, K2O, B2O3, BaO, ZnO, PbO, etc., can make the bending strength of porcelain enamel increase, especially the role of Na2O, K2O is even more.

Bending strength is also related to the content of emulsion, SnO₂ to improve the bending strength of porcelain enamel is beneficial.

In addition, the bending strength and enamel fusing degree and the firing of enamel products also have a relationship. Incomplete or excessive melting of enamel and excessive firing of enamel products are not good for bending strength. Increase the tensile strength of the enamel, compressive strength and elasticity, the bending strength of the enamel layer are beneficial, reduce the thickness of the enamel layer, it can significantly improve the bending strength of the enamel layer.

(D) elasticity

Object deformation under the action of external forces, when the external force disappears, the object can restore the original shape of the nature called elasticity. Elasticity is numerically expressed in terms of the modulus of elasticity of the object, the larger the modulus of elasticity, the worse the elasticity. Elasticity is one of the important physical properties of porcelain enamel. Porcelain enamel good elasticity can cushion the role of external forces or internal stress and reduce the chances of cracking; if the enamel poor elasticity, even if the expansion coefficient of metal and porcelain enamel is very close, or even equal, the porcelain layer of enamel products are also easy to crack. Conversely, if the expansion coefficient of porcelain enamel than the metal is small, as long as its elasticity is sufficient to offset the stress generated by thermal expansion, porcelain enamel can still be firmly combined with the metal, and not broken.

The elasticity of porcelain enamel for enamel products at the edge of the arc, especially in the smaller radius of curvature, especially important.

The elastic modulus of enamel is generally in (6~10)x104MPa.

The elasticity of porcelain enamel is related to its chemical composition, K2O, Na2O, Al2O3, etc. can make the elasticity of porcelain enamel increase. the content of B₂O3 is below 15%, with the increase of content, the elasticity increases; the content is above 15%, with the increase of content and the elasticity becomes worse.

The grinding and addition of clay and the fine pores present in the enamel layer can improve the elasticity of the enamel layer to a great extent. Decrease the thickness of the enamel layer, can also make the elasticity of the enamel layer improved. The elasticity of enamel products deteriorates when the firing temperature is too high or too long.

At room temperature and low temperature, the elastic deformation of porcelain enamel follows Hooke's law.

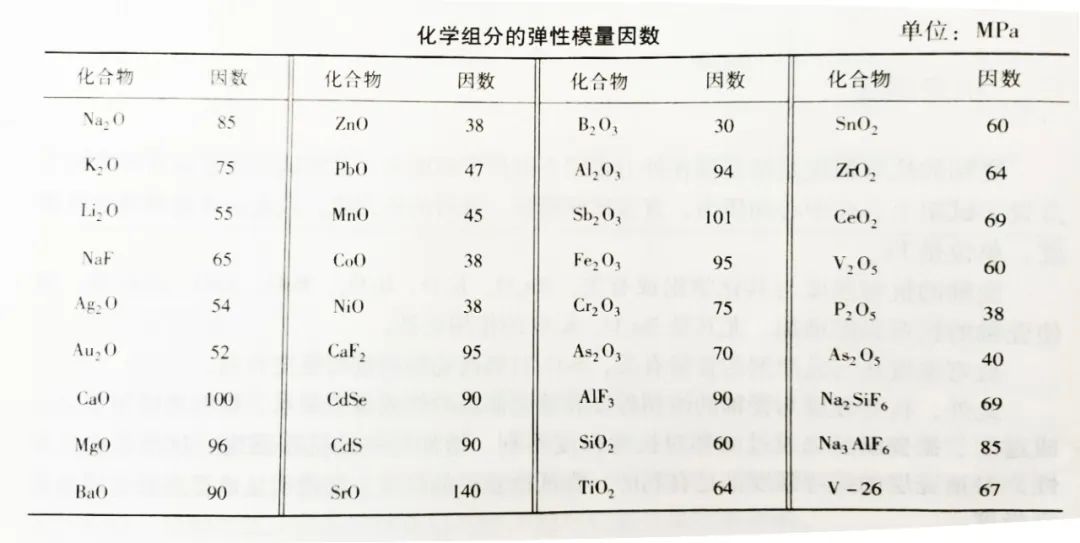

In a certain range, the elastic modulus of porcelain enamel can be calculated by the summation method, see formula:

E elastic = W1E1 + W2E2 + ... +WnEn

Where: E bullet - enamel modulus of elasticity;

Wn - the mass fraction of each chemical component of the enamel;

En-elastic modulus factor of each chemical component of the enamel, MPa (see the table below).

Today's introduction to this end, we will continue to update, welcome to follow us, take you to understand more knowledge of glass-lined glaze ~