Physicochemical properties of enamel glazes

The physicochemical properties of enamel glaze are usually divided into the following categories:

I. Mechanical properties

Second, thermal properties

Three, optical properties

Four, chemical stability

Five, other properties of enamel

This issue, we will introduce the mechanical properties of tensile strength and compressive strength.

Enamel mechanical properties is the enamel or porcelain layer in the process of stress, from the beginning of the load to be destroyed, the maximum stress value, that is, the ultimate strength. Porcelain enamel and porcelain layer are brittle material, its compressive strength and hardness is relatively high. And bending and tensile strength is relatively low.

(A) Tensile strength

The tensile strength of porcelain enamel is the tension needed to make the unit area of porcelain enamel rupture, the unit is Pa. Porcelain enamel is a bad conductor of heat, in the cooling process, the surface cooling speed is fast, shrinkage is also fast, and the inner layer cooling speed is slow, shrinkage is also slow, the surface temperature and the inner layer temperature is not consistent, the surface layer will be subject to tensile stress, and the inner layer will be subject to compressive stress, if this tensile stress is greater than the tensile strength of porcelain enamel, the surface layer will be cracked . The tensile strength of porcelain enamel is generally 40~90MPa.

The tensile strength of the enamel layer is closely related to the tensile strength of the enamel. The tensile strength of enamel mainly depends on its chemical composition, when B2O3 below 15%, BaO and CaO below 25% with the content of the increase in tensile strength, Cr, Si, Ti and other oxides to improve the tensile strength of the enamel layer is very favorable. The tensile strength of the enamel layer is a positive correlation with the tensile strength of the enamel, and in most cases can even be said to be indistinguishable from each other. This is also true for compressive strength, elasticity and many other properties.

The tensile strength of the enamel is also related to the fusing of the enamel, which decreases if it is overfused.

The tensile strength of porcelain enamel in a certain range can be calculated by the following formula:

Where: ωn a porcelain enamel each chemical component of the mass fraction;

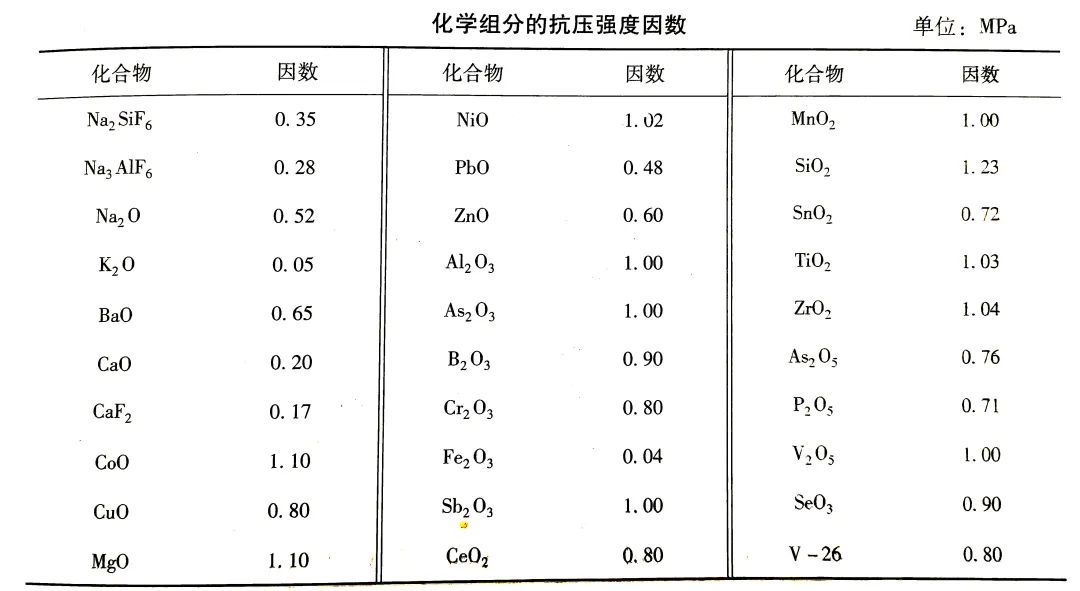

Pn a chemical component of the tensile strength factor, MPa (see the following table) .

(B) Compressive strength

The compressive strength of enamel is the pressure needed to make the enamel of unit area break, unit is Pa.

Because the expansion coefficient of porcelain enamel is smaller than that of metal blank, therefore, after the product is fired and cooled, the bad tire imposes a relatively large compressive stress on the enamel layer, and if this compressive stress exceeds the compressive strength of porcelain enamel, the enamel layer will produce cracks or deceramic. Therefore, the compressive strength of porcelain enamel is very important for the solid combination of enamel layer and blank.

The compressive strength of porcelain enamel is 10~20 times of its tensile strength, generally in 600~1500MPa.

The compressive strength of porcelain enamel is closely related to its chemical composition, B2O3, CaO, MgO, BaO, AL2O3, ZnO, etc. can improve the compressive strength of porcelain enamel, of which AL2O3 has a greater role in improving the compressive strength of porcelain enamel, the content of CaO is below 5%, the content of MgO is below 10%, the role of improving the compressive strength of porcelain enamel is enhanced with the increase of its content.

The formula for calculating the compressive strength of porcelain enamel is as follows:

Where: P pressure a porcelain enamel compressive strength;

ωn a porcelain enamel each chemical component of the mass fraction;

Pn a porcelain enamel chemical components of the compressive strength factor, MPa (see the following table ) .

This is the end of today's introduction, we will continue to update, welcome to follow us, bring you more knowledge of glass-lined glaze ~

Reference: "Enamel and Glass Enamel".