Physicochemical properties of enamel glazes

The physicochemical properties of enamel glaze are usually divided into the following categories:

I. Mechanical properties

Second, thermal properties

Three, optical properties

Four, chemical stability

Five, enamel other properties

Mechanical properties are subdivided into:

(A) tensile strength

(B) compressive strength

(C) flexural strength

(D) elasticity

(E) hardness

(F) density

(G) impact strength

(H) Adhesion strength

In the first two issues, we introduced the mechanical properties of tensile strength, compressive strength, flexural strength, elasticity, hardness and density, in this issue, we will introduce the impact strength and adhesion strength of enamel.

(vii) Impact resistance strength

Impact strength is the ability of an object to resist the impact of another object to withstand.

The impact strength of enamel products, said to cause the porcelain layer was destroyed or porcelain layer from the metal blank on the work done by the external force, expressed in J (Jiao).

The impact strength of the enamel, is the concentration of various mechanical properties of the enamel, reflecting the hardness of the enamel and enamel layer, elasticity, compressive strength, bending strength and enamel layer and metal billet combination degree of good or bad.

The impact strength of enamel products, depending on the shape of the product and the test site, the test results are different. As the enamel layer in the curved and edge parts of the greater stress, these parts of the impact strength is less than the plane.

The impact strength of enamel products, not only depends on the above mechanical properties, the thickness of the blank also has a great impact on it. The thicker the blank, under the action of the impact force, the product is not easy to deformation, the enamel layer is also not easy to be destroyed, that is, the greater the impact strength.

The relationship between the thickness of the enamel layer and the impact strength is: the porcelain layer thickens, impact strength decreases.

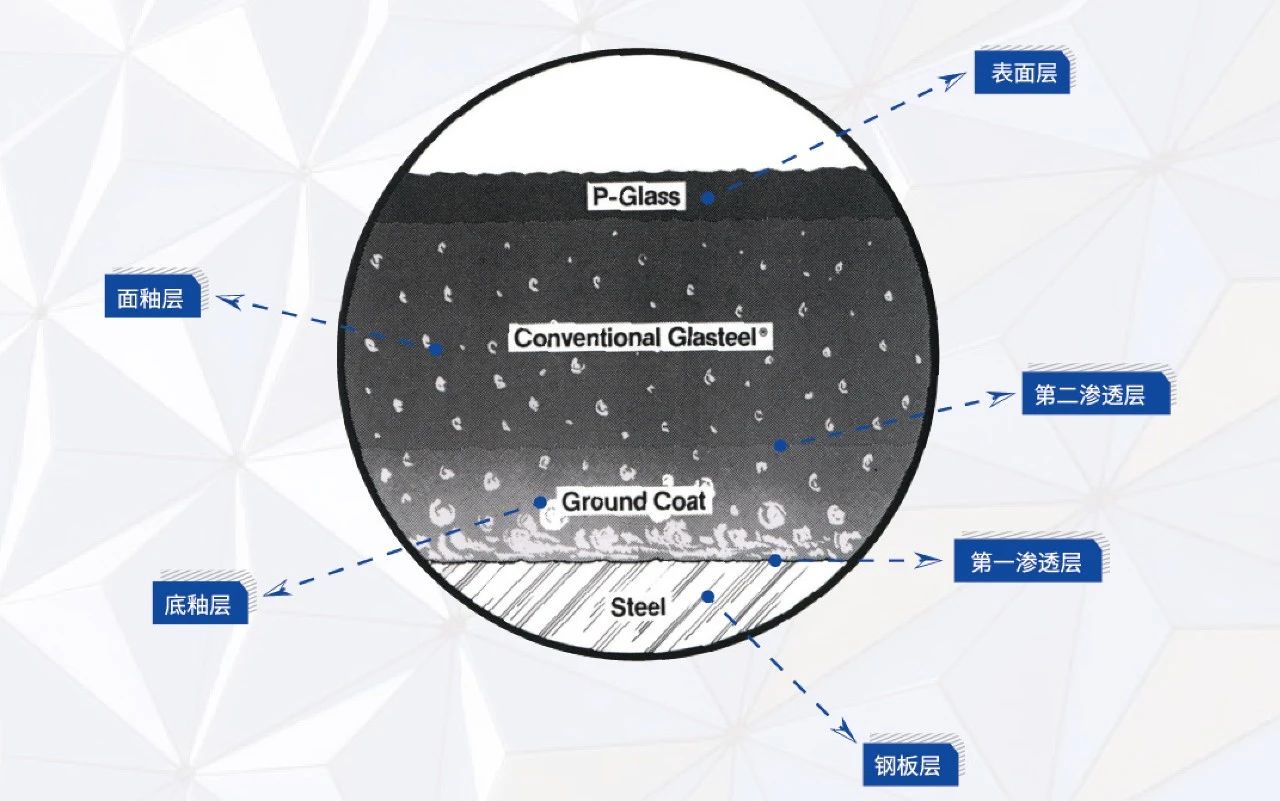

(H) the dense strength

Enamel dense strength reflects the bottom glaze layer and metal blank combination of the degree of superiority, it is to the enamel surface by the impact of the bottom glaze layer to determine the degree of metal, generally divided into four kinds of silk, mesh, block and light plate, which is the best silk, mesh, followed by the block is worse, the worst light plate.

Filamentous: enamel layer tested, porcelain layer peeled off after showing a small amount of points, lines of exposed metal.

Mesh: enamel layer tested, the porcelain layer peeled off after showing a network of exposed metal.

Block: enamel layer tested, porcelain layer peeled off after showing a large area of exposed metal, test points only have a small amount of the bottom glaze.

Light plate: enamel layer tested, porcelain layer peeled off after the full exposure of metal.

Currently, foreign countries use the five-stage method to test the strength of enamel adhesion.

Enamel adhesion performance and enamel melt surface tension has a great relationship. Surface tension and poor wettability of the enamel, can not produce good adhesion with the metal.

Enamel dense strength, and the formulation of the introduction of the type and amount of dense agent is closely related. The introduction of CoO and NiO dense effect is the best, and the amount of attraction does not need to be very high. Generally, good adhesion can be achieved when the content of CoO reaches 0.5% or NiO reaches 1%~1.5%. If CoO and NiO are introduced at the same time, the adhesion effect is better. Adding a certain amount of Sb203 and MoO3 in the base glaze can also improve the adhesion strength.

Porcelain enamel attracts adhesives, mainly to promote the molten enamel to the metal surface, the greater the effect of etching, the more conducive to adhesion. In addition to the strength of adhesion with the introduction of the type and amount of adhesives, and the surface state of the metal, cleanliness, etc. have a close relationship. The adhesion strength of the rough surface is better than that of the smooth surface of the billet.

The degree of melting of the base glaze has a great influence on the adhesion strength. Fusing too transparent and incomplete fusing, the dense enamel are unfavorable, but also produce other defects.

The firing process is also important to the adhesion strength of enamel products, over or under firing of enamel products, the adhesion is poor.

This is the end of today's introduction, we will continue to update, welcome to follow us, bring you more knowledge of glass enamel glaze ~