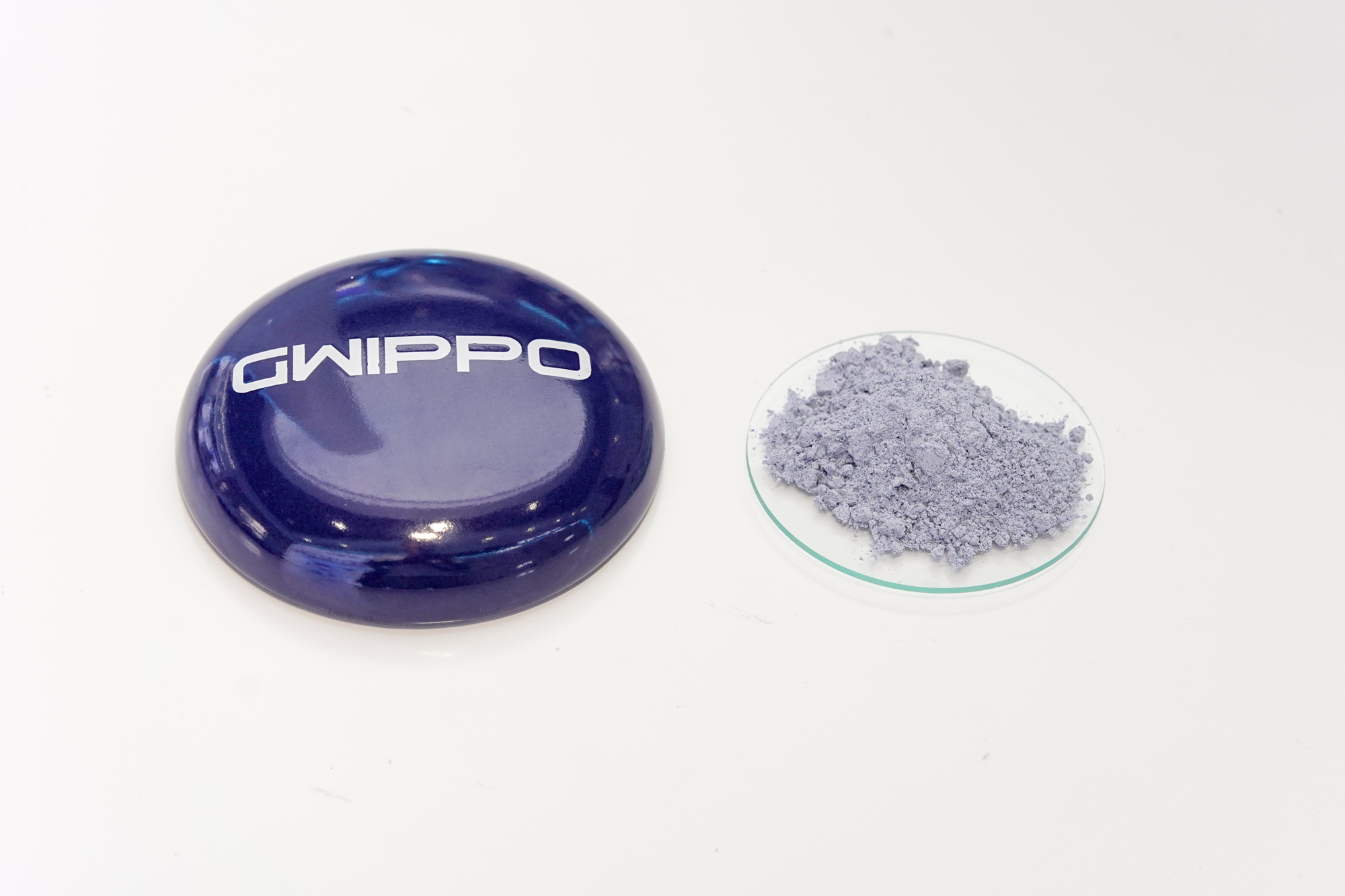

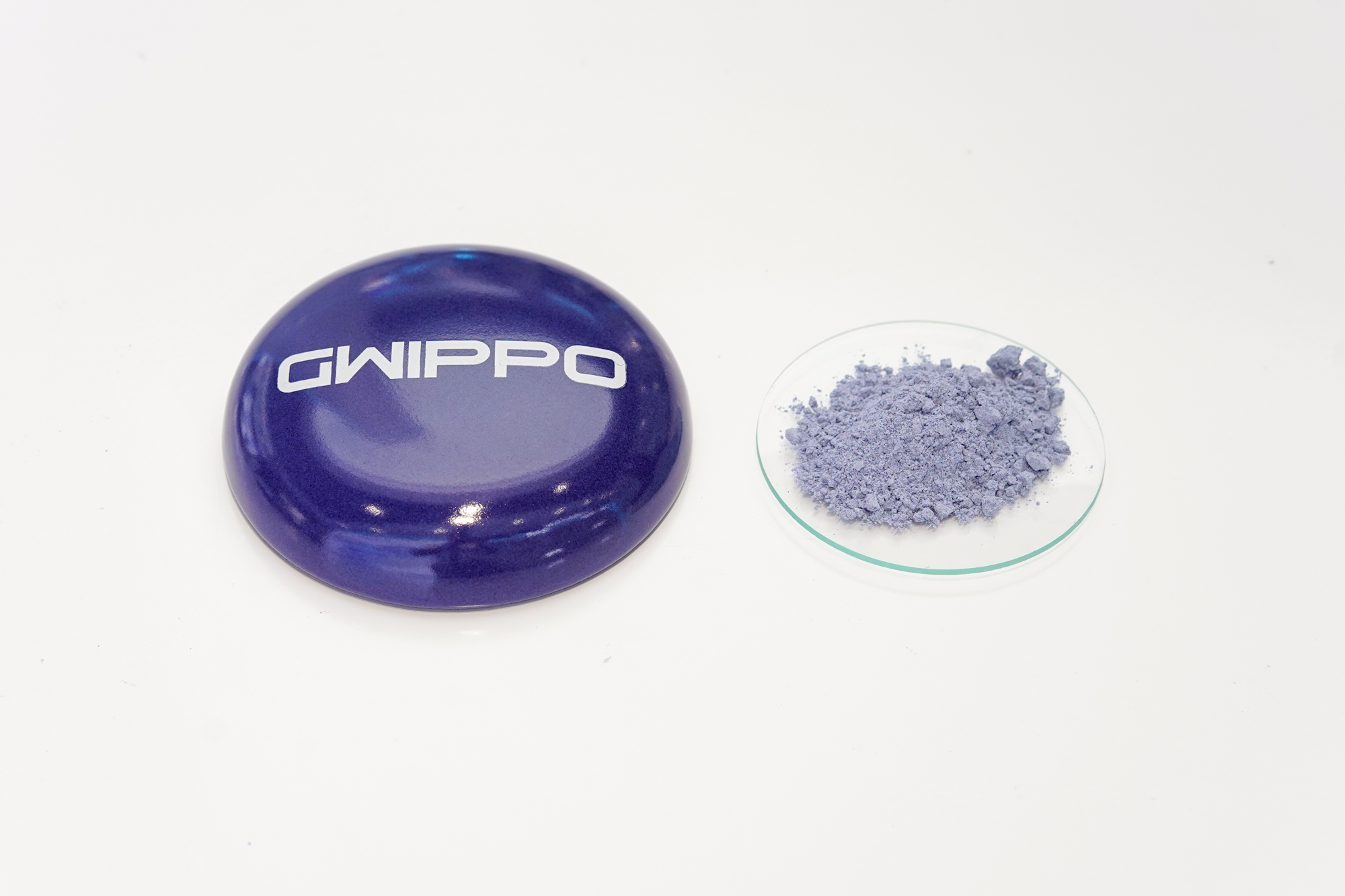

| Product Image | Number | Category | Main performance | Enamel Craft | Burn temperature |

|

L-01(P) | Pre -grinding powder | Water heater liners and coils for sandblasting and pickling processes. | Wet dip enameling | 830-850℃ |

|

L03-A697 | Pre -grinding powder | Excellent physical and chemical properties (resistance to boiling water erosion loss of weight ≤ 3.9g/m², resistance to alkali erosion loss of weight ≤ 0.14mg/cm²); cobalt blue color; porcelain surface fine and Good gloss; Flowability. Good retention | Wet dip/spray enameling | 850-860℃ |

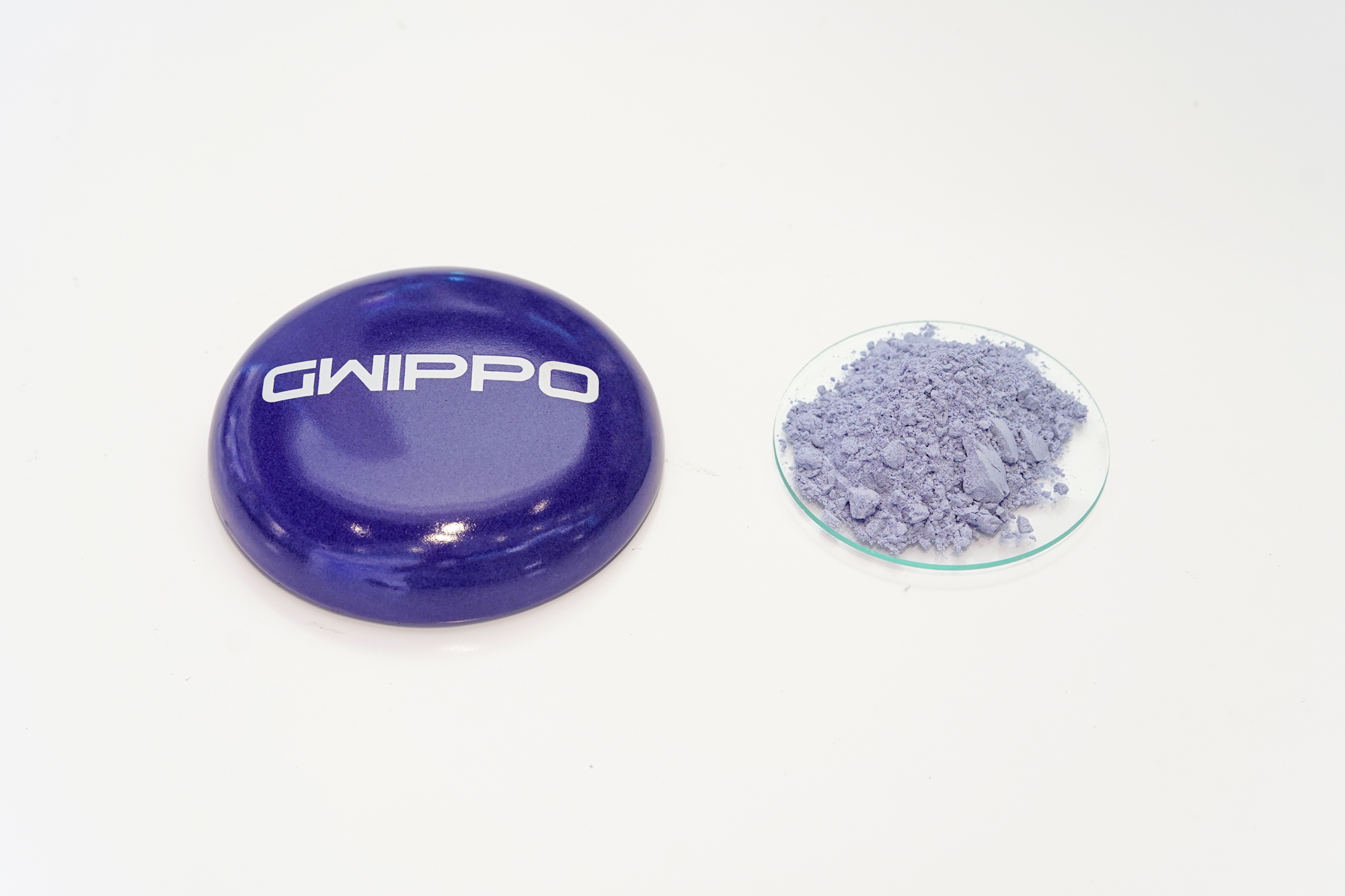

| Product Image | Number | Category | Main performance | Enamel Craft | Burn temperature |

|

LJ-01 | Pre -grinding powder | Excellent physical and chemical performance (weight -resistant erosion weight ≤4.5g/m², alkaline resistance weight loss weight ≤ 0.14 mg/cm²); good flowing; | Wet dip enameling | 850-860℃ |

|

L-01(3) | Pre -grinding powder | Excellent glaze retention, suitable for sandblasted water heater liners. | Wet dip enameling | 830-850℃ |

|

L-01(A6910H1) | Pre -grinding powder | Adhesion class 1, wide firing range, excellent ring seam coverage. Suitable for sandblasted water heater liners. | Wet dip enameling | 850-860℃ |

|

L-01(7) | Pre -grinding powder | Adhesion grade 1, good glaze retention, suitable for water heater liners with sandblasting process. | Wet dip enameling | 850-860℃ |

|

L-01(10) | Pre -grinding powder | Good flowability, low firing temperature, suitable for sandblasting and pickling process water heater inner liner | Wet dip enameling | 830-840℃ |

|

L-01(11) | Pre -grinding powder | Adhesion level 1, good flowability, low firing temperature, suitable for sandblasting process of human water heater liner | Wet dip enameling | 830-840℃ |

|

L-01(H1) | Pre -grinding powder | Excellent physical and chemical properties (resistance to boiling water erosion loss of weight ≤ 3.9g/m², resistance to alkali erosion loss of weight ≤ 0.14mg/cm²); cobalt blue color; porcelain surface fine and Good gloss; Flowability. Good retention | Wet dip enameling | 850-860℃ |

|

L-01(104) | Pre -grinding powder | Excellent physical and chemical properties (resistance to boiling water erosion loss of weight ≤ 3.9g/m², resistance to alkali erosion loss of weight ≤ 0.14mg/cm²); cobalt blue color; porcelain surface fine and Good gloss; Flowability. Good retention | Wet dip enameling | 850-860℃ |

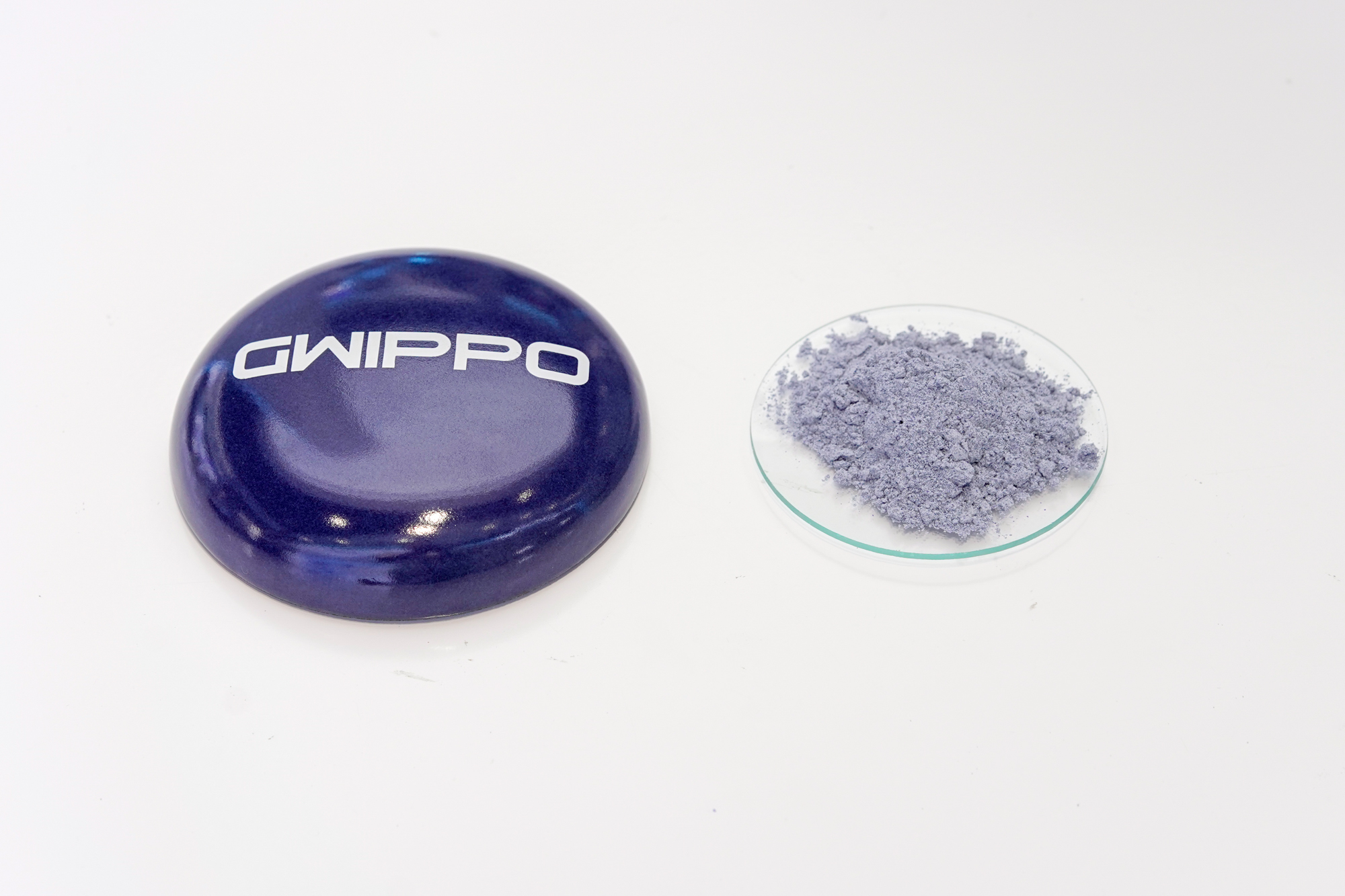

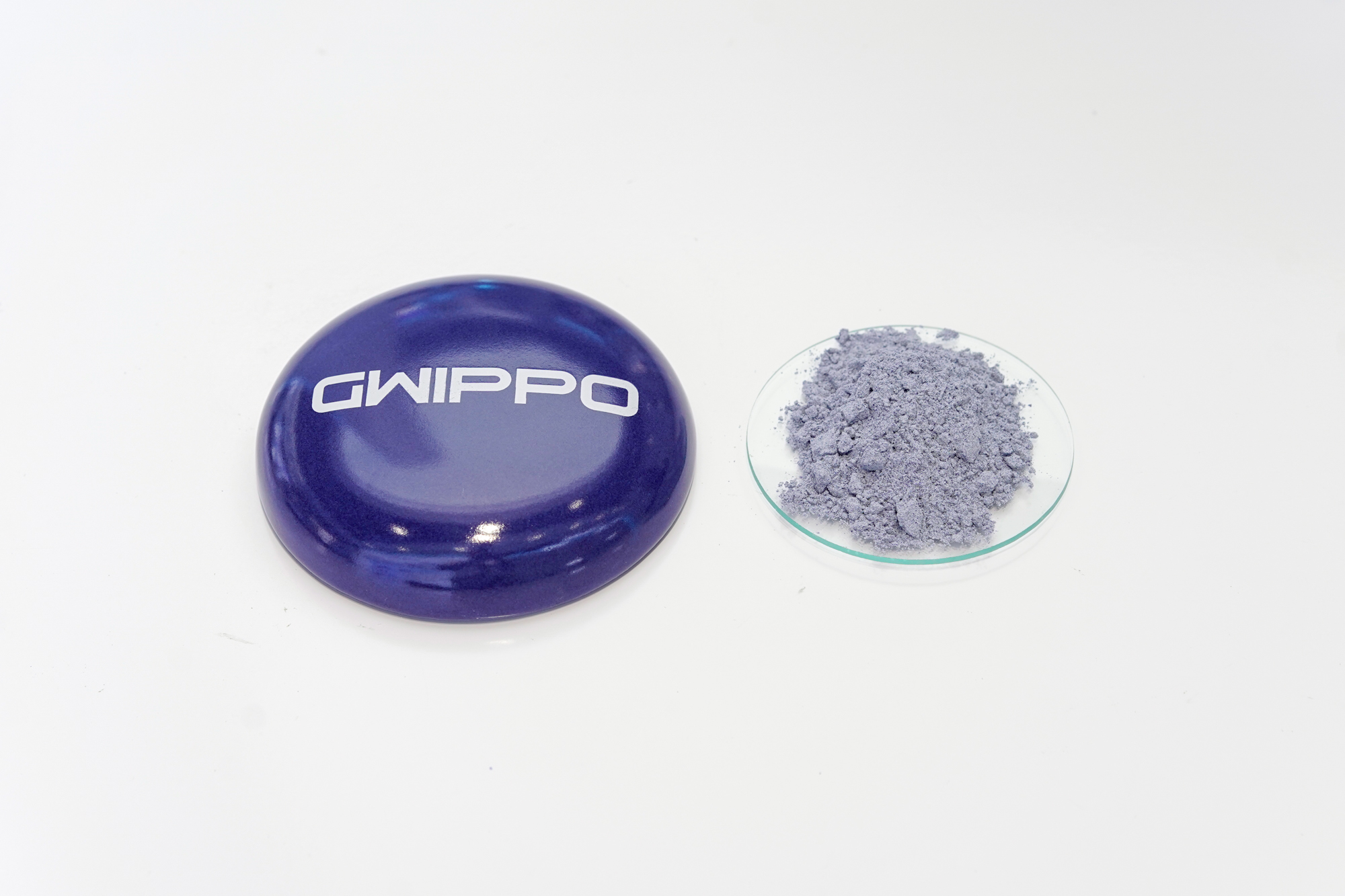

| Product Image | Number | Category | Main performance | Enamel Craft | Burn temperature |

|

L-01B | Pre -grinding powder | Excellent physical and chemical properties (weight loss by erosion in boiling water ≤ 4.5g/m². Loss of weight by alkali erosion ≤ 0.14mg/cm²); Adhesion class 1; Suitable for Water heater inner liner of sand blasting process and pickling process. | Wet dip enameling | 850-860℃ |

|

L-01(L) | Pre -grinding powder | Stable glaze performance, easy to operate; suitable for butt and plug welded water heater liners, good coverage; suitable for sandblasting process water heater liners | Wet dip enameling | 830-850℃ |

|

Enamel glaze powder | Pre-ground slurry | Excellent physical and chemical properties (weight loss by erosion in boiling water≤2.3g/m². Alkali erosion loss resistance ≤0.12mg/cm²); good gloss of porcelain surface; excellent bubble structure; suitable for sandblasting process of water heater inner liner | Wet dip enameling | 830-850℃ |

E-mail: ky@gwippo.com / zj@gwippo.com

Tel: +86-510-86685125

Mobile phone: 13621535272

Copyright © GWIPPO All rights reserved. Support:Bomin